Client’s Intro: China Minmetals Corporation, one of China’s largest state-owned metals and mineral trading companies, sought to establish a state-of-the-art battery recycling facility to process end-of-life electric vehicle batteries.

Challenges

- Manual disassembly processes were hazardous for workers due to potential thermal runaway and chemical exposure

- Low processing capacity of only 200 batteries per day with manual methods

- Inconsistent material recovery rates averaging 75-80%

- Difficulty in handling diverse battery formats and chemistries

- Compliance with stringent environmental regulations

ALB Solution

- Automated Battery Sorting System: AI-powered vision system to identify battery types, chemistries, and conditions

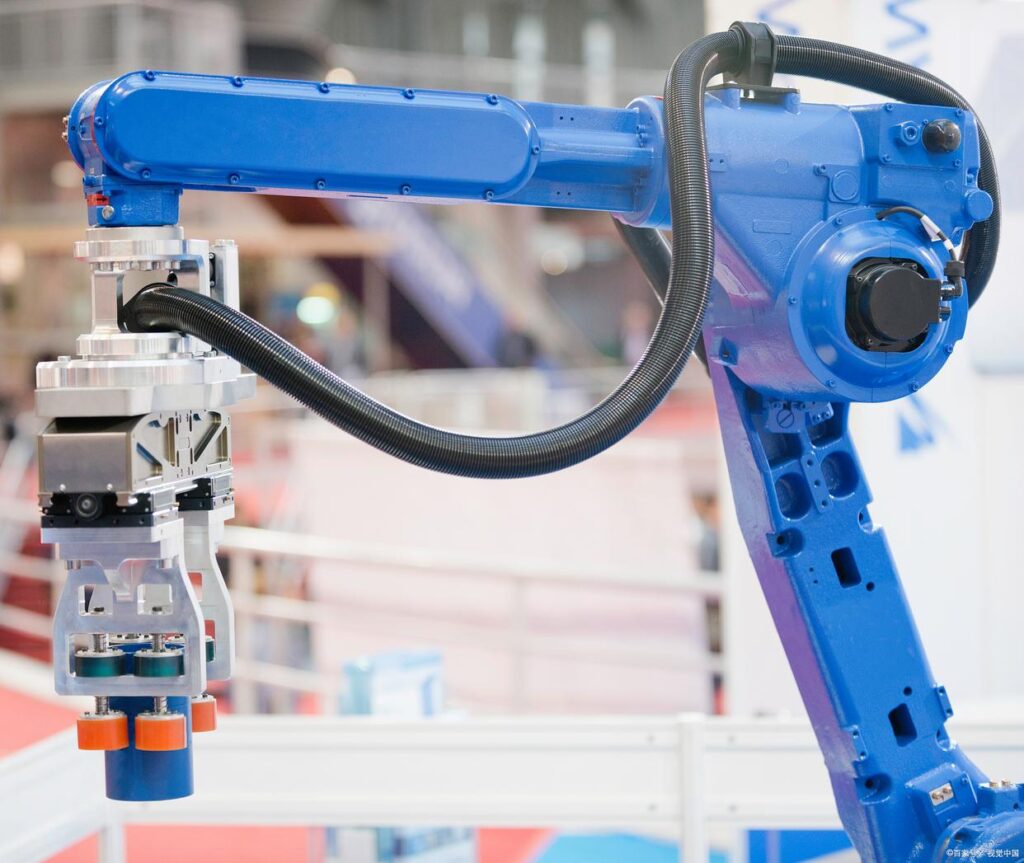

- Robotic Disassembly Cells: Customized robotic workcells with specialized end-effectors for different battery formats

- Precision Discharge System: Controlled discharge process to minimize fire risks

- Material Separation Technology: Advanced separation techniques for copper, aluminum, black mass, and other valuable materials

- Integrated Safety Systems: Comprehensive fire suppression, ventilation, and emergency shutdown systems

- Real-time Monitoring: IoT sensors and data analytics for process optimization

Key Results

- Increased processing capacity from 200 to 1,000 batteries per day

- Achieved material recovery rate of 95%, significantly higher than industry average

- Eliminated manual handling risks with fully automated processes

- Reduced operational costs by 40% through automation and efficiency improvements

- Enabled 24/7 operation with minimal human intervention

- Exceeded environmental compliance standards with zero hazardous waste discharge